The Three Key Components of a Successful IoT & AI-Based Solution for Restaurant Operations

Operating restaurants in 2021 and beyond requires using tech-based ingredients in a new recipe

The COVID-19 pandemic has redefined how restaurant operators conduct operations. It has called for a re-examination of business processes so restaurants can re-open, remain operational and cater to customers, most of whom arrive with a safety-fi rst mindset

Technology can help address the challenges of providing healthy air quality and optimum food safety, two vital factors that are defi ning the dining experience this year. In 2021, restaurant operations require a sprinkling of AI, a dash of IoT, a scoop of remote service and a cup of changing processes to run optimally.

RFMA’s facilities resource manager, Jeff Dover, CRFP, had a great conversation with Parminder Singh, head of solution engineering at EcoEnergy Insights, on what a recipe of such technologies might look like and what benefits it could serve up.

Jeff Dover: What new technology-driven ingredients are going to be key to restaurant operations in 2021 and beyond?

Parminder Singh: Restaurant operators need a few pieces, or ingredients, in order to successfully manage restaurant equipment. These include:

- Edge intelligence hardware, which can easily integrate with, monitor and control underlying equipment and sensors. It should be able to communicate bi-directionally with the cloud.

- Cloud analytics platform, which allows users visibility into operations of various building equipment and the ability to control them. It also needs the capability to analyze data from across the restaurant network and offer predictive actionable insights. Actionable insights are key as this enables operators to be proactive and address small issues before they grow into larger problems

- Remote support, which provides a team of multi-disciplinary experts to put the insights into action and deliver outcomes.

When these ingredients work together, bringing their own strengths to the recipe, restaurant operators can manage and monitor the restaurants effectively. Data is fed to the cloud platform from the hardware installed in the restaurants, and the platform applies its intelligence to generate insights, which should be predictive and actionable. Today, there are platforms that can act autonomously on these insights too, depending on the level of intelligence of the underlying equipment, and can optimize their performance. They can also inform users of the solution via a mobile or desktop application to take a corrective action. The third ingredient, preferably a 24x7 remote operations center, continuously monitors the restaurants and equipment and frequently executes and reports on the implementation of the operational improvement strategies.

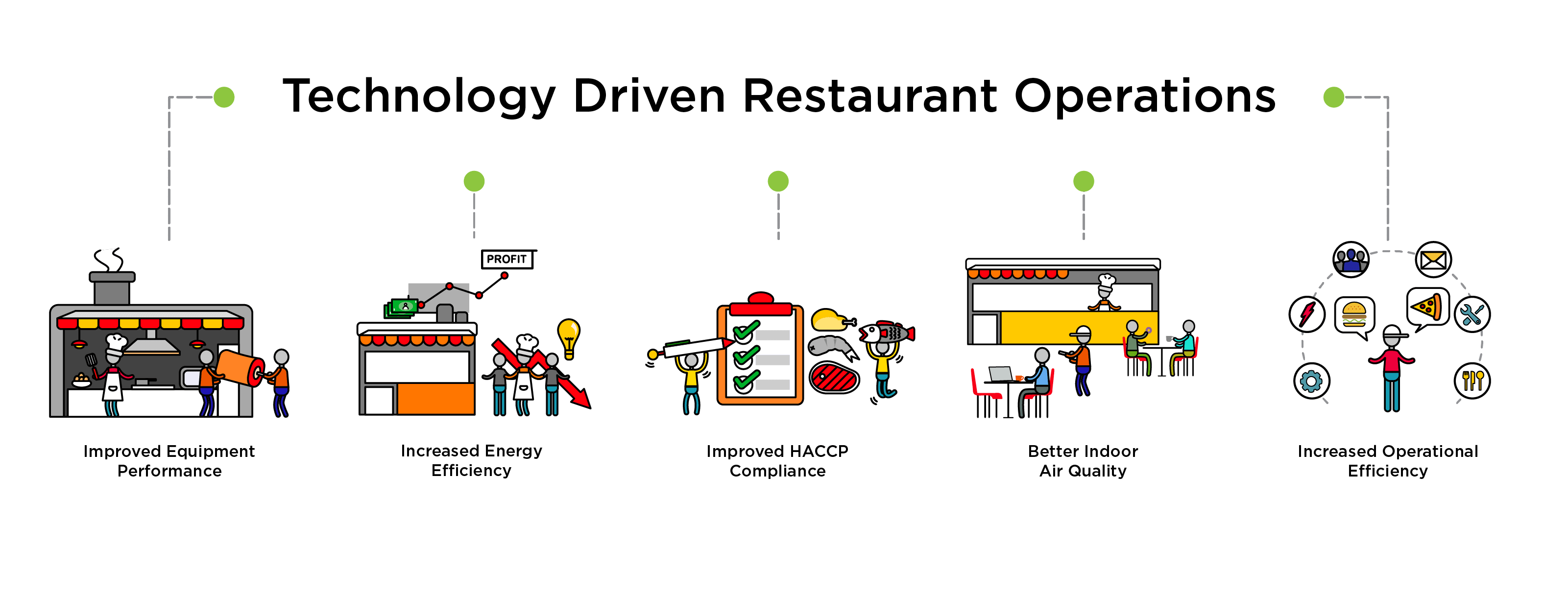

This model of operations can help improve operating equipment such as HVAC, refrigeration, lighting and cooking equipment, which leads to better control of aspects like indoor air quality, occupant comfort, food safety, and energy and operational efficiency.

Dover: Air quality is top of mind for diners this year. How can restaurant HVAC equipment be monitored and controlled to keep guests and employees safe from possible COVID-19 transmission? Given that the employees may be wearing masks, how can they also be made comfortable inside the restaurant?

Singh: Managing indoor air quality has become critical during the COVID-19 pandemic, and we see all our clients focus on providing a healthier indoor environment for their employees and customers.

A technology suite, like the one I outlined, improves air quality by purging air before starting up (in case doors have been shut for a long time) and enables higher ventilation during operation. Operators can also monitor and maintain relative humidity within the recommended range. They can monitor set points and schedules regularly and take corrective action the moment they receive insights of any deviations or likely equipment performance issues that could snowball into a major problem, addressing them before they happen.

Here are a few of actions restaurant operators may take with such technology solutions:

- Automated air purge and regular air circulation as recommended by the likes of ASHRAE

- Proactive & automated HVAC strategies set up to eject stale air every morning before opening

- Highly responsive temperature and schedule management of HVAC equipment.

With regards to the ambience in the restaurants and ensuring occupant comfort, here are the capabilities that operators may leverage:

- Monitor airflow, air distribution and humidity as per available guidelines and best practices

- Schedule regular filter cleanings

- Identify equipment that need servicing or preventive maintenance and schedule them in advance rather than just responding to breakdown and all the negative aspects associated with it – downtime, loss of businesses, labor and repair costs.

Dover: How is food being monitored and prepared in accordance with local health department standards?

Singh: A guest’s experience in a restaurant is defined by food safety and taste. Today, the need to reassure customers about food safety has only gotten amplified.

IoT solutions today allow refrigeration temperature monitoring and even hazard analysis and critical control points (HACCP) monitoring. This not only monitors the temperature of the cooler/freezer, but can also detect the number of times the door was opened and for how long.

The system could also be set up to provide alerts and actionable insights if the parameters go out of range (based on local health department standards and HACCP guidelines) or if the probability of failure of any of the equipment increases.

The system could also automate the food safety logs electronically, which can be presented to the local health department during audits. This also helps operators to chalk out improvement plans, whether related to employee awareness or equipment maintenance.

Today, the simple use case of maintaining the right temperature setting for the refrigeration equipment is enabling restaurant operators to minimize the HACCP deviations and food wastage.

Dover: How does the system ensure cooking equipment is operating properly and being maintained so guests know they are receiving high quality products?

Singh: Data can be picked up from a variety of cooking equipment and can be used to provide alerts and actionable insights. Restaurant operators can:

- Monitor operating performance of key cooking equipment like fryers, ovens and grills

- Monitor the run hours of the equipment and even be advised on when a maintenance event should be scheduled

- Receive alerts on when a restaurant misses a maintenance event

- Compare an equipment’s current operational performance with the benchmark data and trigger a maintenance call if required.

- Restaurant operators can communicate with confidence that they are proactively monitoring and maintaining cooking equipment, almost as a doctor would monitor the health of a patient, to provide quality dishes to their customers.

Dover: What additional features can such systems provide to ensure other critical pieces of equipment are being properly monitored and maintained and operating efficiently?

Singh: The capabilities of such systems are ever evolving. As equipment becomes smarter in terms of offering data and controls and as we collect more data from equipment, we are able to spot more trends, improve control logics and optimize algorithms.

Even today, such technologies can further help operators by:

- Automatically staggering the startup and shutdown of equipment, to reduce the energy consumption and utility demand

- Automatically executing morning fire up and night shut down schedules for HVAC and kitchen equipment

- Identifying anomalies in operating conditions that could lead to a potential breakdown

- Monitoring critical parameters like oil change cycles, efficiency, preheat cycle time and baking temperature

- Regularly monitoring freezer defrost cycles to prevent ice accumulation and avoid breakdowns

- Monitoring HVAC compressor health and identifying early signs of failure

So long as we stay curious and keep looking for what more we can do with the ingredients while also thinking of how we can improve operations, we will be able to find new ways to apply such technologies. Once the key ingredients are in place, operators can always improve and customize the recipe to their liking.